Working method of doctor blade

- Purpose

–scrapes the remaining lacquer from the surface of the printing cylinder

screen rims are free of colour

screen cells are filled perfectly

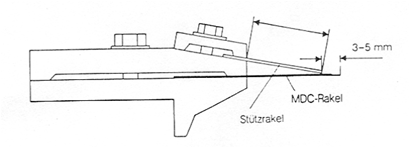

Support doctor blade

prevents:

- Deflexion

- damage of the printing roller

Types of doctor blade

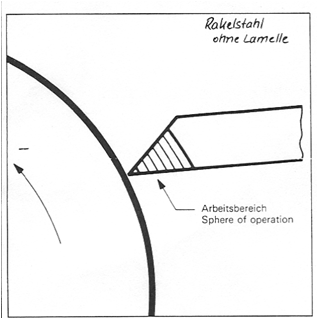

- Doctor blade steel without blade tip

•different coating with progressive attrition

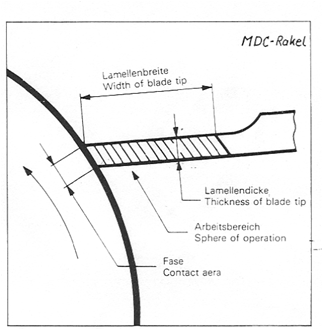

- MDC-doctor blade

•due to steady blade tip the contact area is always the same

Doctor blade – definitions

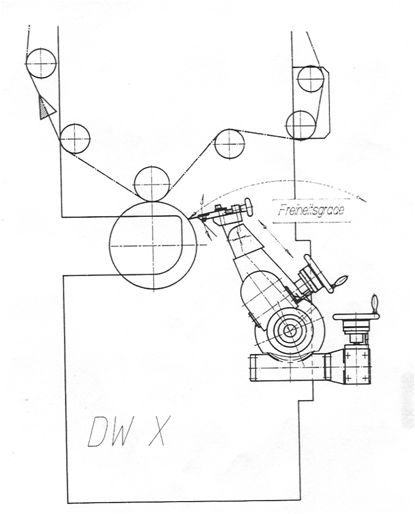

- Doctor blade adjusted in reverse way

–advantage: no blade lines

-disadvantage: difficult to adjust, small range of setting

- Blade oscillation(blade lifting)

•by blade oscillation the doctor blade is scraped over the full width

•without blade oscillation uneven attrition with line screens

- Blade way: Distance from doctor blade to printing line

•long blade way -> solvent evaporates, fine screen cells do not print

•short blade way -> better printed image

- Connection angle of doctor blade and lacquer viscosity

•viscosity lower -> angle of doctor blade steeper

•viscosity higher -> angle of doctor blade more flat

- •Blade pressure

–force which acts on the blade girder (approx. 1-2bar)

- •Line pressure

– pressure of the doctor blade on the gravure roller

– influenced by force on the doctor blade and the angle of the blade

big angle -> small line pressure and vice versa

high line pressure :

high attrition

clean rims

less lacquer coating at few deflexion

Doctor blade – mistakes

Problems by a wrongly adjusted doctor blade

•Uneven lacquer coating over the width

•blade girder or glade carrier deflected or lop-sided

•doctor blade inserted lop-sided

•blade pressure not o.k.

•striped lacquer coating

•blade carrier, support blade dirty

•doctor blade wavy

•too high blade pressure

•blade position too flat •

fine blade lines

•doctor blade with damaged bezel

•support blade damaged

•Chatter marks in the lacquering

•doctor blade unstable, jumps or vibrates

•oscillation worn out

•change-over point no control

•too high blade pressure

•torn-out screen lines

–blade bezel damages

–wrong blade pressure